| SPECIFICATIONS | FHC-85EA FHC-B85EA |

|---|---|

| Length Of Workpieces (mm) | L20-200mm L25~300mm (opt.) |

| Spindle Motor (hp) | 3HP(2.2kw), (2 Pcs), Standard . 2-5 HP(1.5kw~3.75kw), (2 Pcs), Optional |

| Spindle Speed (rpm) | 50Hz (850RPM~1300RPM), 60Hz (1020RPM~1560RPM ) |

| Frequency Converter (kw) | 5.5KW~7.5KW(7.5HP~10HP) (Optional) |

| Air Pressure (mpa) | 6~8 Kg/cm², 120ml/min , 0.6~0.8mpa |

| Cutterhead (mm) | Ø12~Ø52 Standard MAX Ø60, Ø25~Ø80 Optional |

| Pipe and Bar O.D. Outter / I.D. Inner Angle and End Face (mm) |

O.D Ø12~Ø52/t0.8~5 O.D Ø50~Ø80/t0.8~5 |

| Applicable Materials | Various pipes including steel, iron, stainless steel, aluminum, bronze |

| Machine Dimensions (LxWxH) (mm) | 2000x2000x1500 |

| Packing Dimensions (LxWxH) (mm) | 2140x1700x1800 |

| N.W. (kg) | 1290 |

| G.W. (kg) | 1440 |

Auto Matic Model

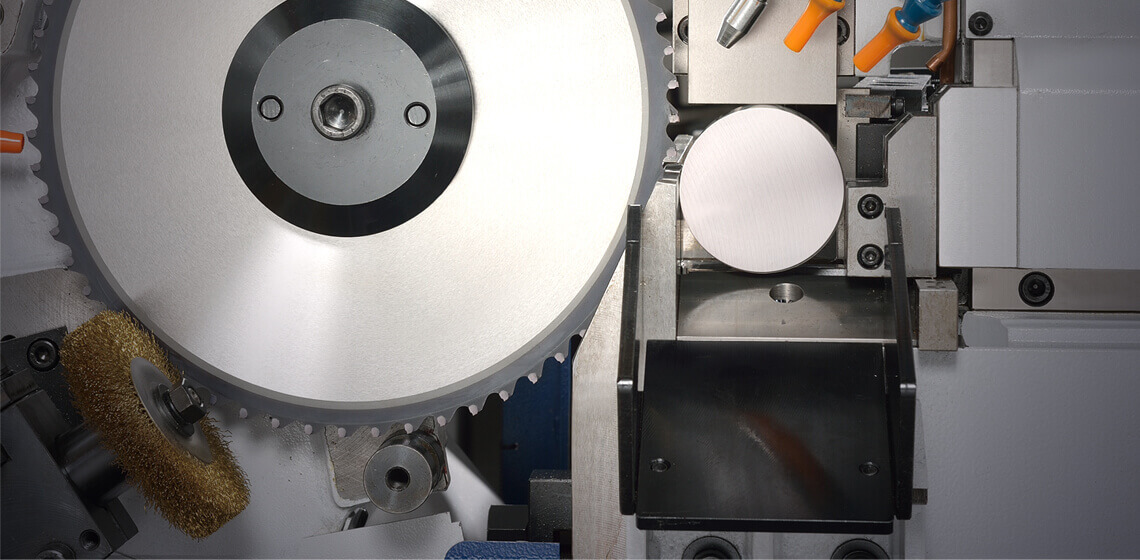

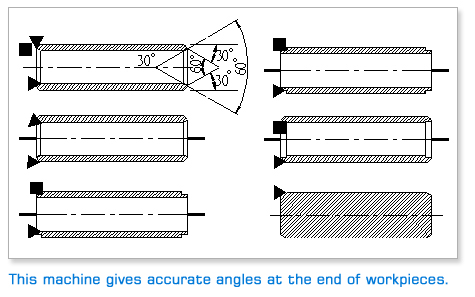

Motion cycle includes automatic material infeed through a channel (automatic feeder is optional). Automatic cutting feeding/retracting and automatic workpiece outfeed. Continuous motion cycles provide high machining speed, high accuracy, reduced labor requirement while greatly upgrading productivity.Normal Method For Pilpe End Chamfering

Standard Cutter、Clamp、Cutter Bit

‧Ø16~Ø10 Chamfering inner and outter angles

‧Ø10~Ø3.2 Chamfering inner and outter angles

‧Ø5~Ø12 Optional cutter head

‧Ø12~Ø52 Standard cutter head (MAX Ø60)

‧Ø25~Ø80 Ø25~Ø150 Standard cutter head

‧FHC-75EA Clamping mold

‧FHC-120EA Clamping mold

‧Chamfering samples

‧New cutter head Φ12 ~Φ120

‧Twin head chamfering clmap Ø12~Ø52

‧82SA Standard clamp Ø10~Ø80

‧150SA Standard clampØ25~Ø150

‧170SA Optional clamp Ø50~Ø170

‧Standard cutterhead for left and right x2 sets

‧Circular clamping mold two pieces in one set

Optional

| NO. | 管徑 Ø | Length L |

| 1. | Ø12~Ø27 | 25~200 mm |

| 2. | Ø16~Ø38 | 100~700 mm |

| 3. | Ø22~Ø50 | 100~1000 mm |

| 4. | Ø38~Ø60 | 100~1200 mm |

| 5. | Ø50~Ø76 | 300~1500 mm |

| 6. | 300~2000 mm | |

| 7. | 300~2500 mm |

Optional Accessories

‧Custom cutterhead