| Model | THC-B70NC |

|---|---|

| Cutting Capacity | TCT carbide sawblade HSS sawblade |

| Round Solid Bar (mm) | 10~70 (Ø8~10 Opt.) |

| Square Solid Bar (mm) | 10~57 |

| Rectangle (mm) | 10~57 |

| Round Pipe (mm) | 10~70 (Ø8~10 Opt.) |

| Square Pipe (mm) | 10~57 |

| Maximum Length of Head Cut (mm) | 10 ~ 60 |

| Waste Material Length at Tail End (mm) | 65~(65 +πCutting length)) |

| Feeding Length (mm) | 5~600 Continuous cycles |

| Manually Stack Line-up Loader Capacity (kg) | 2500 |

| Material Length (mm) | 2000 ~ 6000 |

| Material Loading Width (mm) | 950 |

| Machine Specifications | THC-B70NC |

|---|---|

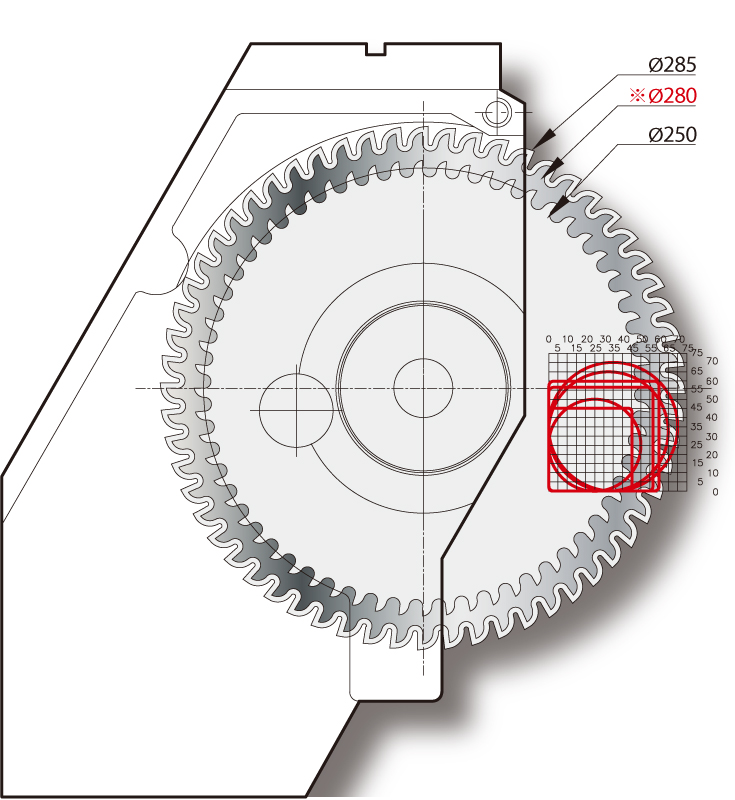

| TCT Carbide Sawblade | Ø250~Ø285 × t2.0 |

| Pin Holes + Bore (mm) | 4 × Ø11 × PCD63 × Ø32 |

| TIP Aluminum Carbide Sawblade (mm) | -- |

| Pin Holes + Bore (mm) | -- |

| HSS Sawblade (mm) | Ø250~Ø285/t1.5~2.5 |

| Spindle Motor (kw) | 7.5 (10HP) |

| Spindle Speeds (rpm) | 17~200 |

| Frequency Inverter (kw) | 2.2 (3HP) |

| Hydraulic Pump Motor (kw) | 2.2 (3HP) |

| Operation Pressure (mpa) | 7mpa 70kg/cm² |

| Oil Tank Capacity (ℓ) | About 100 |

| Air Pressure (mpa) | 0.4~0.6mpa 4~6kg/cm² |

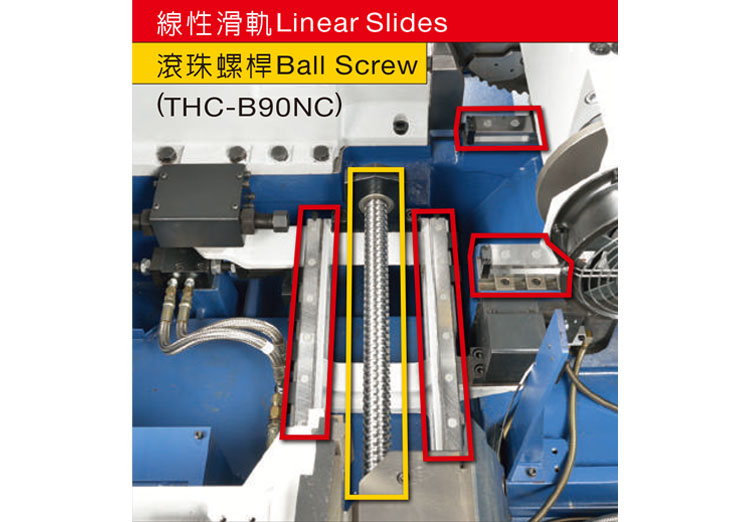

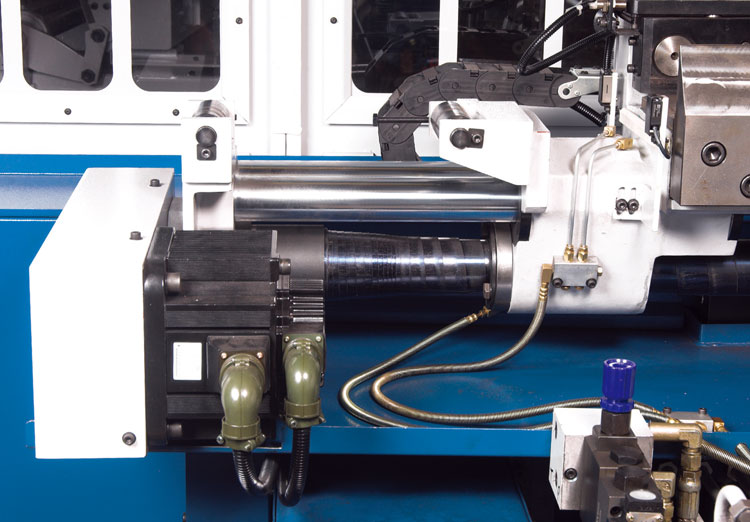

| Feed Drive | AC servo-motor (1.3kw or 1.5kw) and precision ball screw |

| Sawhead Drive | A:Material feeding and cutting is driven by hydraulic system B:AC Servo-motor (1.8kw or 2.0kw) + Ball screw transmission for cutting |

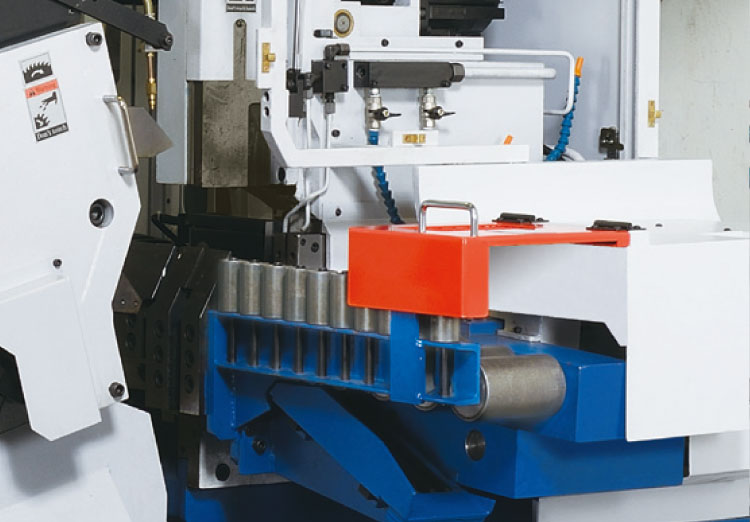

| Feeding Vise | Horizontal hydraulic type |

| Main Vise | Horizontal and vertical hydraulic type , one set each |

| Machine Dimensions and Weight | THC-B70NC |

|---|---|

| Machine Size (mm) | 6650 x 1450 x 1560 |

| Weight (Machine + Feeder) (kg) | 2500 |

Material: Steel Pipe Thickness: ≤2.5 ~ 3.5 mm

| Sawblade Dia. | |||

| Ø250 | Ø50 | 45 x 45 | 40 x 45 |

| ※ Ø280 | Ø65 | 57 x 57 | 52 x 60 |

| Ø285 | Ø70 | 60 x 60 | 55 x 60 |

| Model | Servo-motor Drive Ball Screw Feed | Hydraulic Driven Sawhead Feed for Cutting Motion | Sawhead Driven by Servo-motor Ball Screw Transmission for Cutting |

|---|---|---|---|

| THC-A70NC | |||

| THC-B70NC | |||

| THC-B76NC | |||

| THC-B90NC | |||

| THC-BNA102NC | |||

| THC-A101NC | |||

| THC-B101NC | |||

| THC-A130NC | |||

| THC-B130NC | |||

| THC-A150NC | |||

| THC-B150NC | |||

| THC-A165NC | |||

| THC-B165NC | |||

| THC-NA168NC | |||

| THC-BNA168NC |

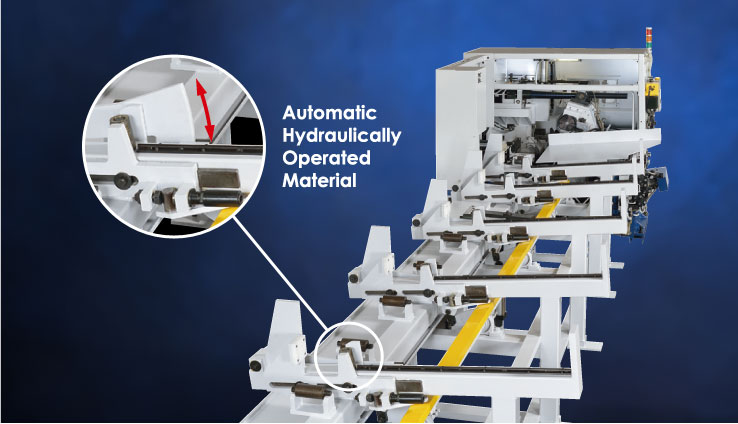

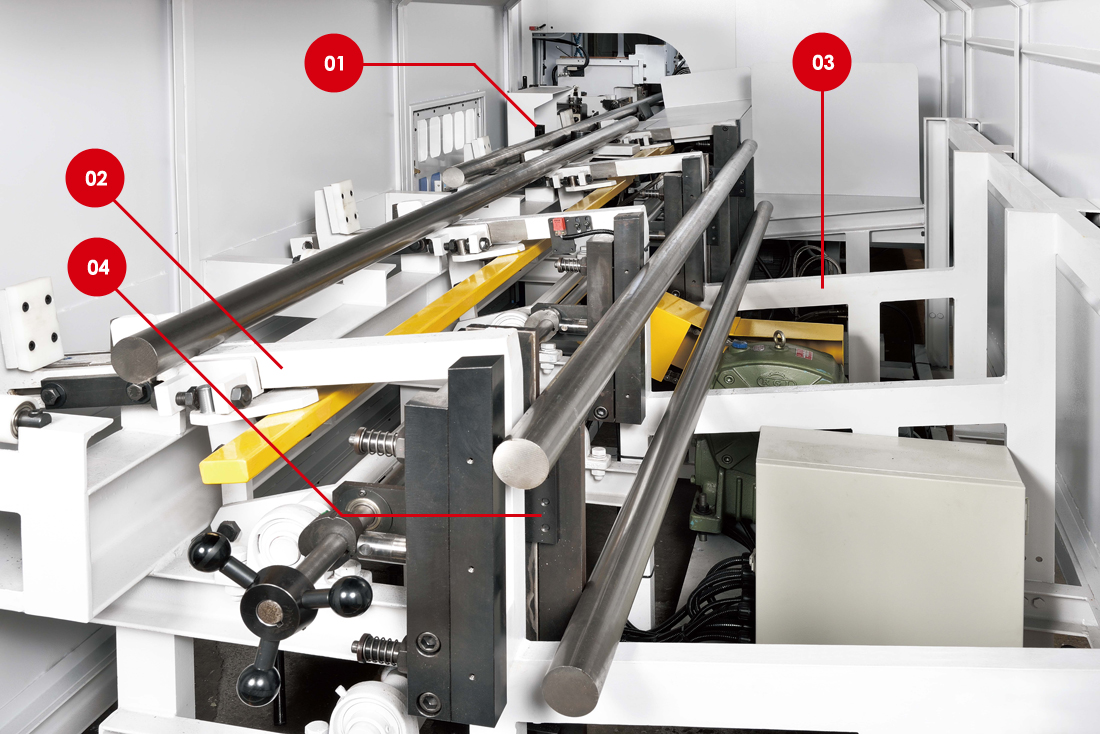

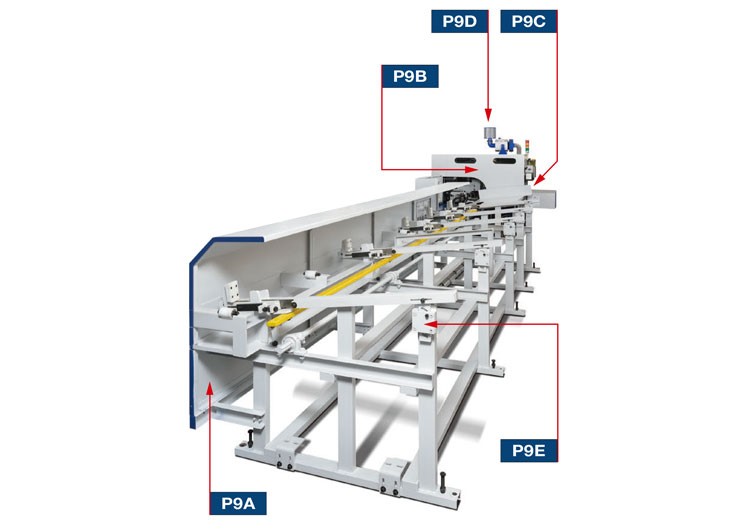

A. Manual Stack Line Up Loader (THC-130NC)

B. Touch Sensing Screen

C. Linear Slides & Ball screw (THC-B90NC)

D. Feed System is Driven by Servo-motor With Ball (THC-B130NC)

E. Mist Lubrication Device

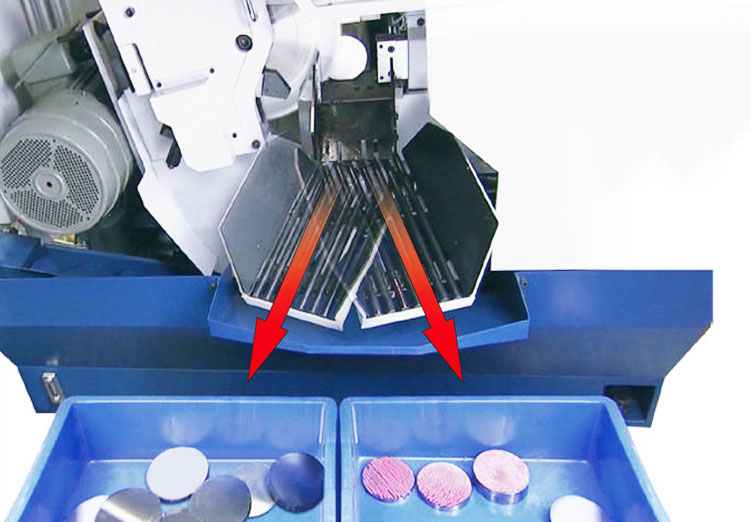

F. Head and Tail Pcs are Separated with Workpieces Automatically

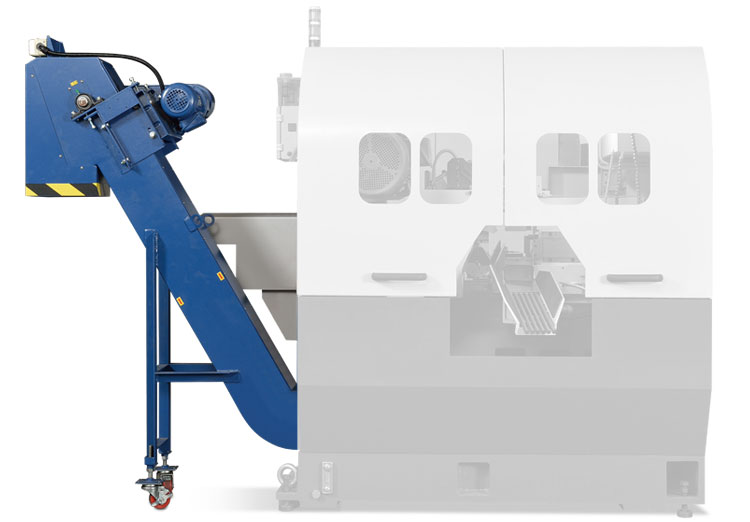

G. Chain Type Chip Conveyor

| Model | Sawblade Gap Compensation Device | Tungsteen Pad for Sawblade Run-out | Chip Removing Steel Brush Wheel | Scraper Type Chip Conveyor | Mist Cooling Device | Cutting Fluid Cooling Device | Angular Steel Slicing Device | Work Light |

|---|---|---|---|---|---|---|---|---|

| THC-A70NC | ||||||||

| THC-B70NC | ||||||||

| THC-B76NC | ||||||||

| THC-B90NC | ||||||||

| THC-BNA102NC | -- | -- | ||||||

| THC-A101NC | -- | |||||||

| THC-B101NC | -- | |||||||

| THC-A130NC | -- | |||||||

| THC-B130NC | -- | |||||||

| THC-A150NC | -- | |||||||

| THC-B150NC | -- | |||||||

| THC-A165NC | -- | |||||||

| THC-B165NC | -- | |||||||

| THC-BA168NC | -- | -- | ||||||

| THC-BNA168NC | -- | -- | -- |

01. Automatic Locating Equipment

02. Automatic Magazine Loader

03. Manual Storage Loader

04. Automatic Lifting Equipment

A. Feeding Safety Guard

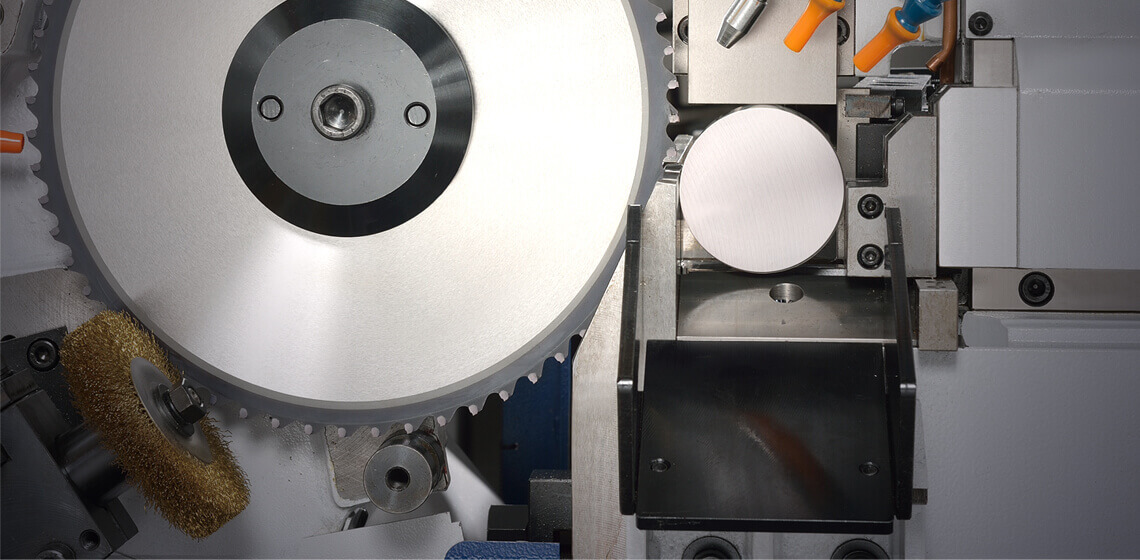

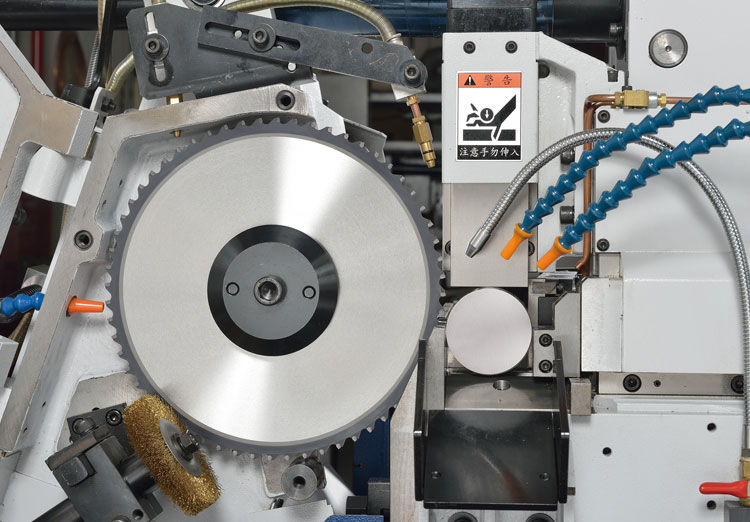

B1. HSS - Circular Saw Blade

B2. TCT - Extra Hard Tungsten Carbide Circular Saw Blade

C. Automatic Roller Out Feeding Device(150~350mm)

D. Oil Mist Collector

E. Angular Steel Slide Assistance Device

| Model | TCT Carbide Sawblade | HSS Sawblade | TIP Aluminum Carbide Sawblade | Aluminum Dust Collector | Oil Mist Collector | Cutting Fluid | Angular Steel Slicing Device | Automatic Roller Out Feeding Device | Manual Storage Loader | Automatic Feeding Equipment | Automatic Magazine Loader | Automatic Locating Equipment |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| THC-A70NC | -- | -- | -- | |||||||||

| THC-B70NC | -- | -- | -- | |||||||||

| THC-B76NC | -- | -- | -- | |||||||||

| THC-B90NC | -- | -- | -- | |||||||||

| THC-BNA102NC | -- | -- | ||||||||||

| THC-A101NC | -- | -- | ||||||||||

| THC-B101NC | -- | -- | ||||||||||

| THC-A130NC | -- | -- | ||||||||||

| THC-B130NC | -- | -- | ||||||||||

| THC-A150NC | -- | -- | -- | |||||||||

| THC-A150NC | -- | -- | -- | |||||||||

| THC-A150NC | -- | -- | -- | |||||||||

| THC-A165NC | -- | -- | -- | |||||||||

| THC-BA168NC | -- | -- | ||||||||||

| THC-BNA168NC | -- | -- |